Although you may run into problems with frozen loads any time of year, due to issues with the reefers, this time of year adds the element of nature to compound the transit problems with produce. There are specific products that are more susceptible to freezing than others, and there are a few places you want to concentrate on looking when a trailer backs in and is ready to unload.

First off, products with higher sugar content usually have a lower freezing point. For example, broccoli and celery will freeze at 31 degrees, while the freezing point of cherries and grapes is about 28 degrees Fahrenheit. Finding the freezing injury on some commodities is relatively easy, such as identifying frozen lettuce, romaine, cucumbers.

Other commodities are more difficult to detect freezing injury, especially if it is slight. Potatoes will breakdown when thawed out, will leak and will produce a strong odor, but in the frozen state they are very difficult to detect. An inspector must take the point of their knife and insert it into the potato about 3/8 inch and twist the knife, hoping to hear a sharp snap. If no snap is heard, the potato most likely is frozen. Sweet peppers are also difficult to detect when freezing injury has affected them, as they will develop sunken pitted areas after they warm up. But catching the problem up front is not easy.

There are a few places you can concentrate your search for possible frozen product:

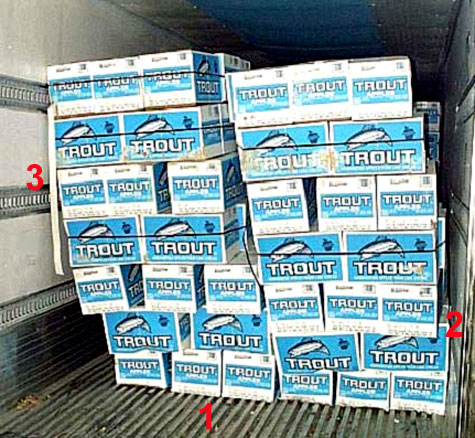

- If you suspect a problem, as you may actually see frost inside the trailer floor or wall, the first pace you would want to look would be product in contact with the trailer floor. Most shippers will stack their product on pallets or lay cardboard down on the floor for protection. Whether the product is floor-stacked or not always zero in on the floor layer containers first.

- The second place to check out would be any containers in contact with the sidewalls. More specifically check the product that would be in contact with the walls. Although the walls are insulated the extreme cold may penetrate the walls and affect the product.

- And lastly you would want to inspect any of the cartons in contact with the metal rails along the sides of the trailer. The metal will act as a conductor for the cold and will cause problems for some products in contact with the metal.

If you do find freezing injury always work you way up from the bottom or in from the sides of the trailer or rail car to determine how extensive the freezing injury may be. If you need to call for a USDA inspection always let the inspector know you have found some freezing injury, point out the location of the problem, and you can even choose to request the inspection be restricted to freezing injury only. They may otherwise miss the freezing injury as they take random samples throughout the load, not necessarily concentrating on the problem areas.

No Comments on “Freezing Problems”